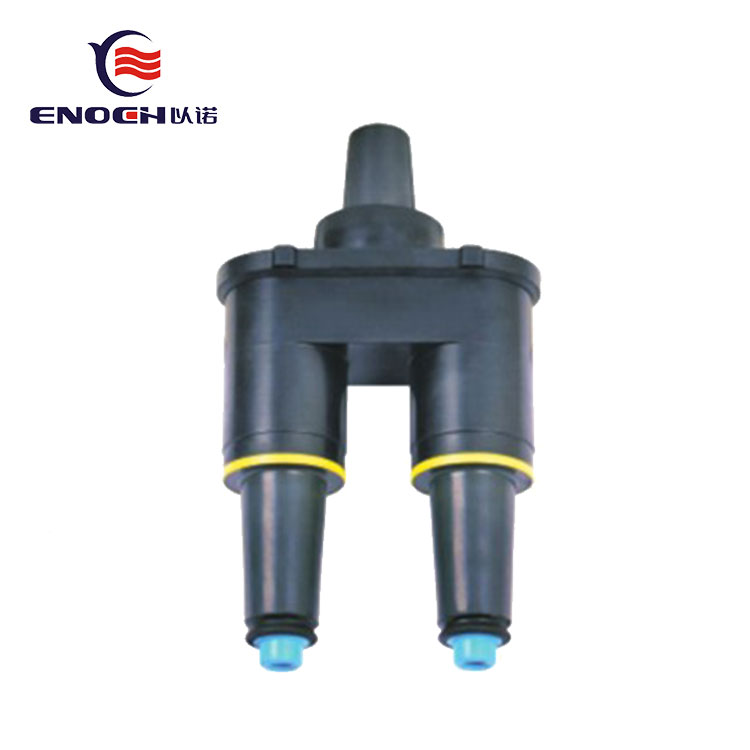

200 A 15kv Loadbreak Elbow

Zhejiang ENOCH electric co.,ltd supply 200 A 15kv Loadbreak Elbow and other power products to numerous companies around the world, including domestic and foreign power bureaus. When the customer confirms, we will carry out production. If have any quality problems, we will solve it. Our aim is to be honest, have sincerity and promise, harmonious and altruistic,that is why the customers choose and believe us.

Send Inquiry

The 200 A 15kv Loadbreak Elbow produced by ENOCH is a fully-shielded and insulated plug-in termination for connecting underground cable to distribution power system of pad-mound transformer, surrounding power supply branch box, cable branch box equipped with deadbreak bushings.

The available conductor cross section for 200A 15kv Loadbreak Elbow is 25mm2-150mm2 for 15kV cable. The conductive pole W/ARC extinguishes function.

Zhejiang ENOCH electric co.,ltd owns dozens of injection equipment,rubber mixing equipment and experimental equipment.Over the years, thanks to the support and love of new and old customers at home and abroad, our 200A 15kv Loadbreak Elbow are exported to Europe and America, Middle East, South Asia and other dozens and regions, creating a good corporate image and reputation. Zhejiang ENOCH electric co.,ltd supply power products to numerous companies around the world, including domestic and foreign power bureaus.

The 200A 15kv Loadbreak Elbow produced by Zhejiang ENOCH electric co.,ltd is a fully shielded and insulated termination for connecting underground cable to transformers, switchgear, and other apparatus equipped with loadbreak bushings, junctions, or other loadbreak connectors.

The Enoch 200A 15kv Loadbreak Elbow meets all the requirements of IEEE Standard 386 and is fully interchangeable with competitor's products and mating products that also meet IEEE Standard 386. Tests conducted in accordance with IEEE/ANSI Standard 386. is Partial discharge minimum extinction boltage-11kV; AC 60Hz for 1min (kV crest)-34kV; Test Point Voltage Test.

Product Specification and Ratings Overview

|

Technical Specification |

|

|

Test Item |

Parameters |

|

Continuous operating voltage |

8.7kV/14.4kV |

|

AC withstand voltage |

45kV/1min |

|

DC withstand voltage |

53kV/15min |

|

1.5/50μs Impulse withstand voltage |

95kV |

|

<10PC Partial discharge voltage |

15kV |

|

Voltage Ratings |

|

|

Voltage Class |

15kV |

|

Max. Voltage Rating Phase to Phase |

14.4kV |

|

Max. Voltage Rating Phase to Ground |

8.3kV |

|

AC 60Hz for 1 Minute |

34kV |

|

DC for 15 Minute |

53kV |

|

BIL and Full Wave Crest |

95kV |

|

Partial discharge minimum extinctior |

11kV |

|

Current Ratings |

|

|

Continuous |

200 amps rms |

|

Switching |

10 operations at 200 amp 10s rms at 14.4kV |

|

Fault Close |

10000 Arms symmetrical at 14.4kV for 0.17s after 10 consecutive successful switching operations |

|

Short Time |

10000 Arms symmetrical for 0.17s 3500 Arms symmetrical for 3.0s |

All the parameters of the 200A 15kv Loadbreak Elbow are in conformity with the requirements and qualified.

Product Features and Performance

The 200A 15kv Loadbreak Elbow are molded using high quality sulfur-cured insulating and semi-conducting EPDM rubber. Standard features include a coppertop connector, tin-plated copper loadbreak probe with an ablative arc-follower tip and stainless steel reinforced pulling-eye. An optional capacitive test point, made of corrosion resistant plastic, is available for use with fault indicators.

Ordering Information

The 200A 15kv Loadbreak Elbow are packaged in a heavy duty polyethylene bag Each Kit contains:

|

1 |

Standard 200A 15kv Loadbreak Elbow Body |

|

2 |

Loadbreak Probe |

|

3 |

Bi-Metal or Copper Compression Connector |

|

4 |

Probe Installation Tool |

|

5 |

Silicone Lubricant |

|

6 |

Installation Instruction Sheet |

|

7 |

Clean Paper |

Please inform the sales staff of the Cable Ranges (Insulation Diameter) and the cross-sectional area of the conductor before purchasing.

|

Cable Ranges (Insulation Diameter) |

||

|

Cable Range Code |

Inches |

Millimeters |

|

A |

0.700-0.920 |

17.8-23.1 |

|

B |

0.780-0.925 |

19.8-23.5 |

|

C |

0.898-1.043 |

22.8-26.5 |

|

E |

0.925-1.028 |

23.5-26.1 |

|

G |

1.043-1.161 |

26.5-29.5 |

|

K |

1.161-1.280 |

29.5-32.5 |

|

Conductor Code Table |

||||

|

Conductor Code |

Concentric or Compressed |

Compact or Solid |

||

|

AWG or kcmil |

mm2 |

AWG or kcmil |

mm2 |

|

|

01 |

#6 |

- |

#4 |

- |

|

02 |

#4 |

- |

#3 |

25 |

|

03 |

#3 |

25 |

#2 |

35 |

|

04 |

#2 |

35 |

#1 |

- |

|

05 |

#1 |

- |

1/0 |

50 |

|

06 |

1/0 |

50 |

2/0 |

70 |

|

07 |

2/0 |

70 |

3/0 |

95 |

|

08 |

3/0 |

95 |

4/0 |

- |

|

09 |

4/0 |

- |

250 |

120 |

|

10 |

250 |

120 |

300 |

- |

Product Structure and Detail

1. SEMICONDUCTING SHIELD. Precision molded peroxide cured semiconducting shield provides ground shield continuity and meets the requirements of IEEE Standard 592.

2. INSULATION LAYER. High quality peroxide cured EPDM Insulation is mixed and formulated in-house for complete control of rubber characteristics.

3. SEMICONDUCTING INSERT. Precision molded peroxide cured semiconducting insert provides corona-free electrostatic shielding of the compression connector.

4. PULLING EYE. Stainless steel pulling eye for hot stick switching operations.

5. COMPRESSION CONNECTOR. Standard Bi-Metal, or optional Copper, compression connector is sized to ensure a cool running connection with maximum current transfer.

6. CAPACITIVE TEST POINT. Capacitive test point on molded T-Body with snap-on cap provides a shielded, hot stick operable means to determine circuit condition.

7. LOADBREAK PROBE. Tin plated copper probe with, arc extinguishing tip, allows for dependable switching operations.

8. DRAIN WIRE TAB. Drain wire tabs provide a convenient point to connect drain wire to ensure grounding of the connector shield.

9. OPTIONAL INTEGRAL JACKET SEAL. The optional integral jacket seal provides a quick and easy means to sealing the cable jacket to prevent moisture ingress. It's available with braided ground strap/bleeder wire for terminating Tape shielded cable.

Product Qualification

1. Excellent quality

Our 200A 15kv Loadbreak Elbow are tested by third party power labs according to IEC standards.The company has obtained ISO9000 quality system certification and environmental protection certification.

2.Professional services

We have been doing advanced research in the field of 200A 15kv Loadbreak Elbow manufacturing. In order to improve the quality and level of service, our personnel completed the QC training, and set up a special inspection department.

3.Powerful technology

Zhejiang ENOCH electric co.,ltd have own factory and have 20 years experience in power connection.

Our Service

Besides our existing products, we can produce various products according to customers' drawings or samples. In the early stage, we will communicate with you in detail. After the product is confirmed, we will give the customer a sample of the goods before production. When the customer confirms, we will carry out production. If have any quality problems, we will solve it.Our aim is to be honest, have sincerity and promise, harmonious and altruistic,that is why the customers choose and believe us.

FAQ

Q1:Can you can design the connectors/bushings according to our size?

A1:Yes

Q2:If OEM is acceptable?

A2:Yes

Q3:Are you a trading company or a manufacturer?

A3:We are a manufacturer.

Q4:How long is your delivery time?

A4:Base on the quantity.

Q5:Where is your factory located?

A5:Lishui city Zhejiang Province China.